TRANSIT TIME DIFFERENCE. DOPPLER.

Ultrasonic flow measurement – For non-invasive ultrasonic flow measurements, Transit Time Difference and Doppler are the two most commonly used techniques. Both methods measure the flow of the medium using sensors that are clamped on the exterior of a pipe. The biggest difference between them is that they each work best in opposite conditions.

Understanding the differences between these methods can help you make the right choice for a successful and efficient installation :

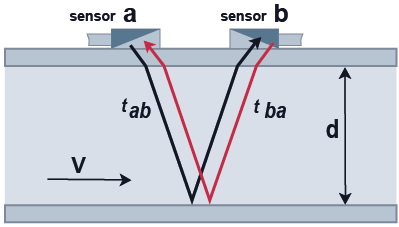

Transit time difference flowmeters measure the time it takes for an ultrasonic signal (sound vibration that is not perceptible to the human ear) to reach the other side of a pipe wall in a diagonal line. Upstream and downstream time measurements are compared. Without flow, the transit time would be the same in both directions. With the flow, the signal moves faster, and slower against it. The measured time difference is directly dependent on the speed of the medium flowing through the pipe or tube. This transit time difference is the relevant value to provide insight into the flow rate of liquids and gases.

Clear liquids and gases

Because the ultrasonic signals must cross the pipe to the receiving sensors, the medium inside the pipe should only contain a minimal concentration of air bubbles or solids (<30%). At a higher concentration, the high-frequency vibrations are damped and therefore too weak to reach the other side of the pipe wall. If that’s the case we advise you to opt for a doppler flow measurement.

Two sensors

In order to be able to realize bi-directional ultrasonic flow measurement, we always supply our transit time difference flow meters with two sensors. Both sensors can send and receive signals.

Very accurate (0.5 – 1%)

With the current generation of transit time difference flowmeters, results are achieved up to 0.5 – 1% accuracy on the current value.

Widely applicable

Transit time difference flow meters are suitable for pipes and tubes of different materials (also double-walled) and with diameters varying from 3 mm to 6500 mm.

Applications : Drinking water, cooling water, water / glycol solutions, hydraulic oil, heating oil and chemicals.

Operating

Doppler flow measurements are based on the principle that sound waves are returned to the transmitter at a different frequency when reflected by something in motion. We hear examples of the “Doppler effect” every day: The clear change in tone of a passing train, an airplane flying over, or the exhaust of a racing car. We perceive a changing tone frequency because we are standing still and the transmitter of the sound is moving.

A doppler flow measurement assumes a linear relationship between this frequency shift and the velocity of the fluid. This is measured as precisely as possible to calculate the flow.

‘Contaminated’ liquids

Doppler flow meters are suited for measuring liquid flows only. And since they are dependent on the reflection of sound, only liquids containing solids and / or air bubbles are suitable for this technique. We are talking about “polluted” water. The most common examples are (mixed) sewage water and waste water. For a concentration < 30 % you should opt for a transit time difference flow measurement.

One or two sensors

Unlike transit time difference flowmeters, which are always supplied with two sensors, doppler flowmeters come in different versions; Either with one or two sensors. Devices with one sensor, have the transmitter and receiver incorporated in the same housing. Devices with two sensors, have one ultrasonic signal sending sensor as well as one receiving sensor.

Accuracy of 2%

Although a doppler ultrasonic flowmeter is assuming that the reflecting particles move at the same speed as the liquid, in reality this is never quite the case. Particles generally tend to settle and gas bubbles rise. As a result, a doppler flow measurement provides a result with an accuracy of 2% on the current value.

Applications

Doppler flow meters are suitable for pipes and tubes of different materials and with diameters ranging from 30 mm to 4000 mm.

Applications: including pump dry running detection, overflow applications and sand extraction.

Transit Time Difference

Doppler

ULTRASONIC FLOW MEASUREMENT. TWO TECHNIQUES, ONE CHOICE.

Transit time difference flow meters are suited for clear liquids such as water, oil and chemicals. Doppler flow meters are suited best for contaminated and bubble-containing liquids such as sewage and waste water. Contact us for specific advice and information on which method is the best choice for your application.